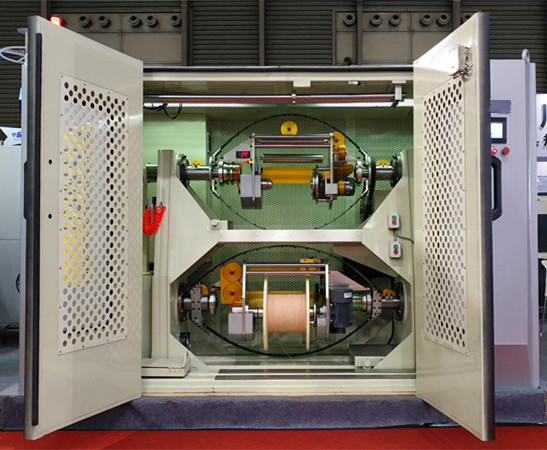

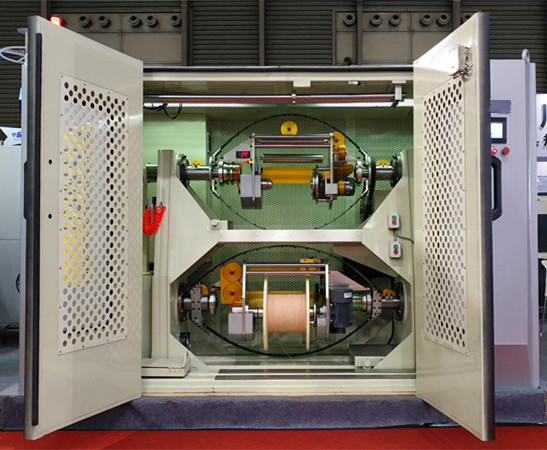

DT500 double layer triple twisting machine

usage:

double layer triple twisting machine used for Lan cable( cat5, cat5e, cat6, cat6e,cat6a, cat7), instrument cable, control cable or other cables two core wires pair twisting, twinning. whole machine PLC control system, easy to operate; Max. 5400TPM, high speed; double layer design, occupied small space. back twist rate can be set on HMI 0-100%.

features:

1. Royal machinery double layer triple twisting machine use triple twisting pitch, when back twist rate at 33%, line speed is 1.5 times of the double twist.

2. Royal machinery double layer triple twisting machine use heave loading design, avoid shaking and noise at high speed running.

3. Royal machinery double layer triple twisting machine use servo motor electrical twist pitch, set pitch on HMI, PLC control, precision+/-2%。

4. Royal machinery double layer triple twisting machine use motor controlled take up tension, tension keep consist from empty reel to full reel.

5. Royal machine double layer triple twisting machine use integrate design, dimension is 3200*1600*1900mm, easy to transport.

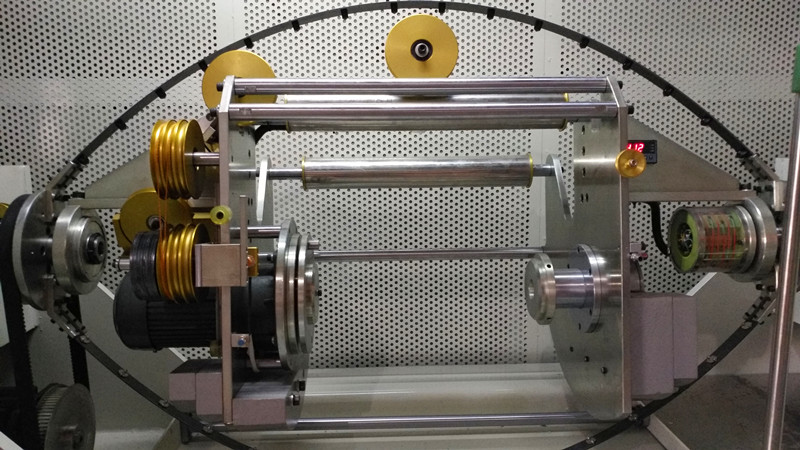

Back twister:

A. Motorized pay-off (outside)

a. Suitable bobbin: ∮500mm*375*∮56mm, or client provide bobbin size.

b. Suitable wire: Φ0.8-1.5mm

c. Pay-off tension: 0.6-3KG

d. Line speed: 250m/min, subject to wire diameter.

e. Brake device: GV18-200W-5S gear motor with dancer wheel.

B. Motorized pay-off (inside)

a. Suitable bobbin: ∮500mm*375*∮56mm, or client provide bobbin size.

b. Suitable wire: Φ0.8-1.5mm

c. Pay-off tension: 0.6-3KG

d. Rotational speed: max. 2000rpm.

e. Line speed: 250m/min, subject to wire diameter.

F. Brake device: GV18-200W-30S gear motor with dancer wheel.

C. Drive

Main drive: 7.5HP AC Futian motor with PG card tracking line speed.

D. Capstan

a. Mode: horizontal type

b. Wire tension: max. 3KG

c. Line speed: 250m/min, subject to wire diameter.

d. Capstan pulley: multi grooves, ∮237.1

e. Drive: 750W Inovance servo motor with driver

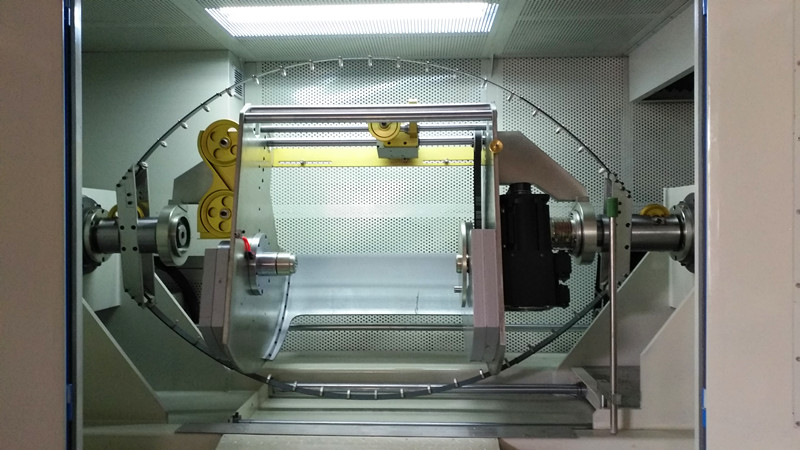

Triple twister:

A. Suitable bobbin: ∮500mm*375*∮56mm, or client provide bobbin size.

B. Line speed: 250m/min, subject to wire diameter.

C. Twisting pitch: 1mm-60mm, set by touch screen.

D. Traverse pitch: max. 10mm

E. Main drive: 7.5HP AC Futian motor with PG card.

F. Bobbin lifting/lowering: by hydraulic

G. Main shaft lubricating: molybdenum disulphide grease lubrication

H. Stop: the machine will automatically stop when wire break interior or exterior or length counter reaches the preset data.

I. Noise index: no more than 85dB

J. Safety: the machine doesn’t run when the door open or the lifter not in the proper position.

Control system:

A. Weilun 5.7 inch touch screen, Siemens PLC

B.Control switches, button, indicator lamps(CHINT), contactors,air switches(SHIHLIN), relays(OMRON)

C.AC Motors made by Futian, Gear Motor made by Tunglee, Frequency Inverter made by Inovance.

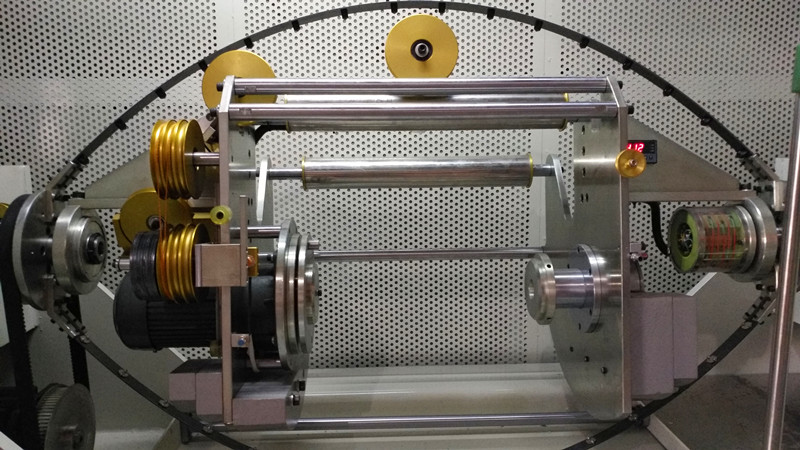

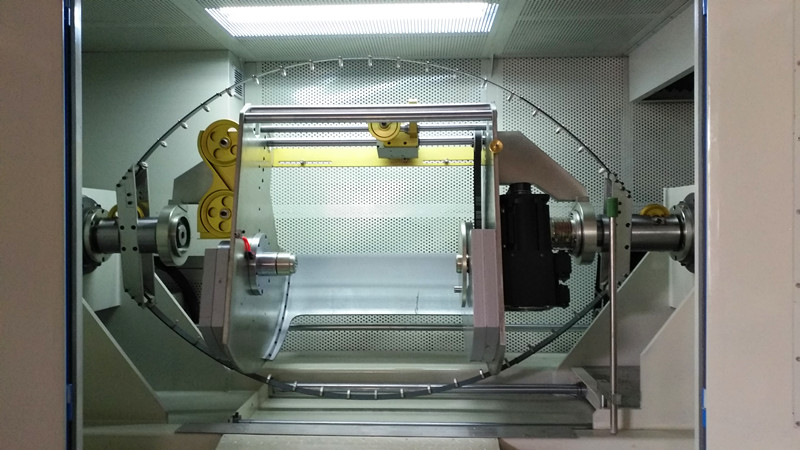

machine inner structure: