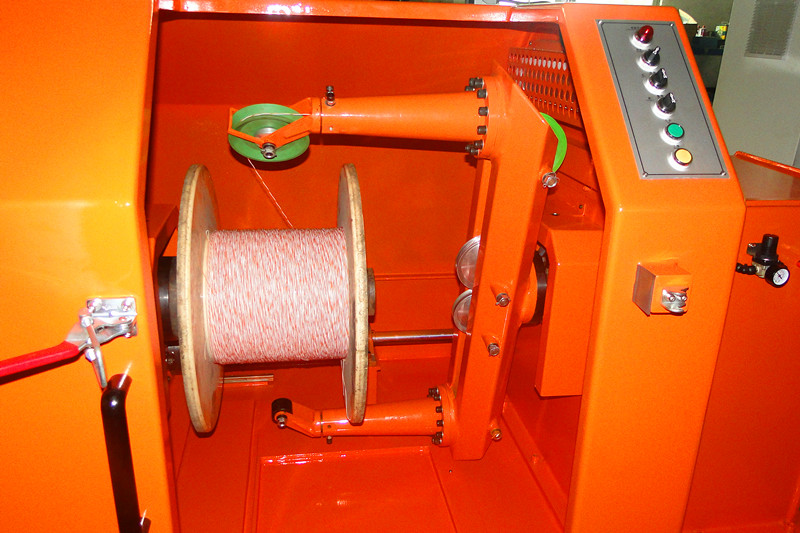

cantilever single twisting machine used for Lan cable, data cable, high frequency cable, instruments cable, HDMI, USB2.0/3.0, control cable, low voltage power cable core wire laying up or twisting. equipped with online taping machine, can finish twisting and taping in one process, high efficiency, quality under control.

machine featuers:

| No. | Item and Specification | quantity | remark |

| tool | |||

| 1 | tool box (middle) | 1 PC | |

| 2 | socket head spanner | 1 suit | |

| 3 | scissor | 1 PC | |

| 4 | screw driver (both "-", "+") | 1 suit | |

| 5 | monkey spanner (10") | 1 PC | |

| 6 | nipper pliers | 1 PC | |

| 7 | sizing block | 1 PC | |

| 8 | remove spanner | 1 suit | |

| 9 | iron pad | 1 suit | |

| easy-wearing parts | |||

| 1 | indicator | 1 suit | |

| 2 | switches | 1 suit | |

| 3 | relay | 1 suit | |

| 4 | guiding pulleys | 1 suit | |

| 5 | bearing | 1 suit | |

| 6 | belt | 1 suit | |

| 7 | precise PCB | 2 PCs | |

| 8 | traverse screw | 1 PC | |

| 9 | precision potentiometer | 1 PC | |

| manuals | |||

| 1 | machine operation manual | ||

| 2 | motor manual | ||

| 3 | inverter manual | ||

| drawings | |||

| 1 | electrical drawings | 1 PC | |

| 2 | layout drawings | 1 PC | |